Products Details

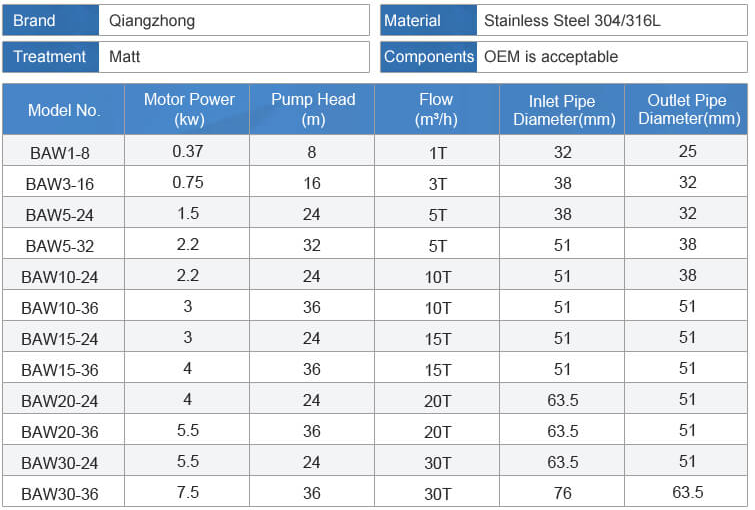

Product Parameters

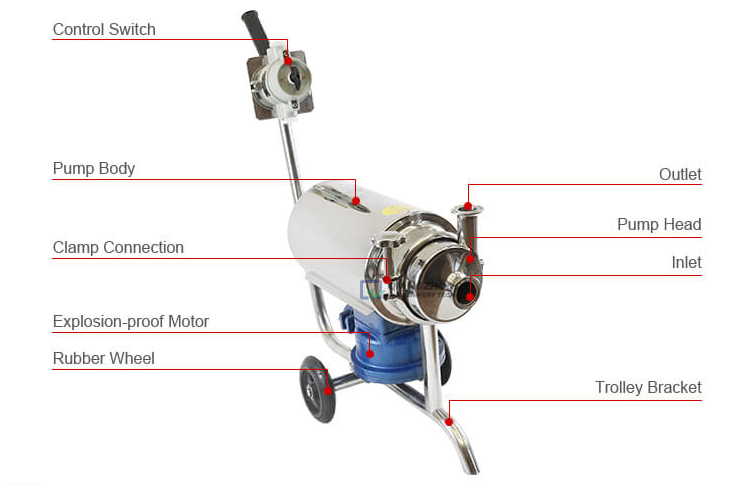

Product Parameters  Product Structure ● The is mainly composed of a pump body, a pump base, and a motor part. Each part is connected by a bolt. The supporting feet of the base can be freely adjusted to facilitate installation without a fixed mounting base. The outlet pipe can be installed vertically or horizontally according to different needs. ● It adopts a smooth transition, rigid structure and thick-walled design. The parts including the pump body, pump cover, impeller part and the part in contact with the material are all made of stainless steel (AISI316 or AISI304). Mechanical shaft seals are made of high quality stainless steel and silicon carbide. Greatly improved wear resistance and moisturization, extending the useful life. ● The pump body and the impeller adopt the integral precision casting and surface of all parts are treated. With special fixtures to assist installation, ensuring an accurate dimensional clearance. The shaft seal adopts the open type structure, so even a small amount of leakage at the shaft seal can be observed in time. It also ensures that even if the leakage is not noticed within a short time, it will not overflow in the motor, thus ensuring a good service life of the motor.

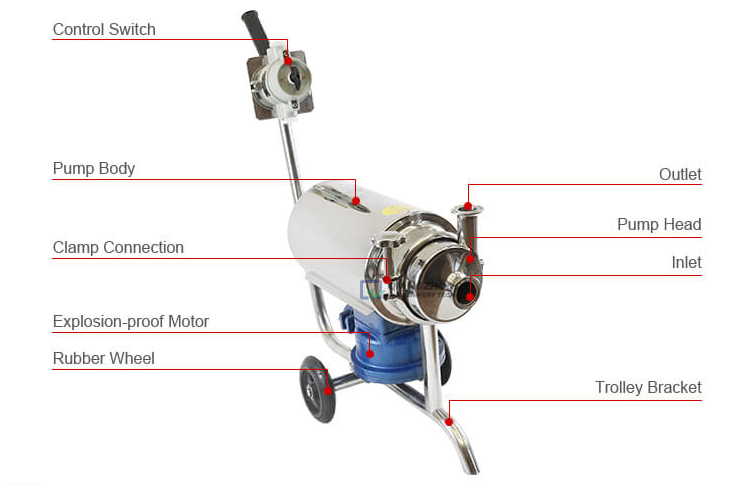

Product Structure ● The is mainly composed of a pump body, a pump base, and a motor part. Each part is connected by a bolt. The supporting feet of the base can be freely adjusted to facilitate installation without a fixed mounting base. The outlet pipe can be installed vertically or horizontally according to different needs. ● It adopts a smooth transition, rigid structure and thick-walled design. The parts including the pump body, pump cover, impeller part and the part in contact with the material are all made of stainless steel (AISI316 or AISI304). Mechanical shaft seals are made of high quality stainless steel and silicon carbide. Greatly improved wear resistance and moisturization, extending the useful life. ● The pump body and the impeller adopt the integral precision casting and surface of all parts are treated. With special fixtures to assist installation, ensuring an accurate dimensional clearance. The shaft seal adopts the open type structure, so even a small amount of leakage at the shaft seal can be observed in time. It also ensures that even if the leakage is not noticed within a short time, it will not overflow in the motor, thus ensuring a good service life of the motor.  Working Principle Stainless steel sanitary pump (also known as milk pump, beverage pump) is a single-stage, single-suction sanitary pump, suitable for conveying milk, beverages, wine and other liquids. It is an indispensable conveying equipment for food, chemical, pharmaceutical and other industries. It is particularly suitable to be used in tube-type sterilization, yogurt temperature-holding equipment, CIP cleaning and other resistance systems. The impeller is inside the pump casing and it rotates with the pump shaft. The impeller blade transfers energy to the fluid in the form of kinetic energy and pressure energy. The pump can't rotate in the reverse direction and the correct direction of rotation is clockwise, which can be seen from the back of the motor.

Working Principle Stainless steel sanitary pump (also known as milk pump, beverage pump) is a single-stage, single-suction sanitary pump, suitable for conveying milk, beverages, wine and other liquids. It is an indispensable conveying equipment for food, chemical, pharmaceutical and other industries. It is particularly suitable to be used in tube-type sterilization, yogurt temperature-holding equipment, CIP cleaning and other resistance systems. The impeller is inside the pump casing and it rotates with the pump shaft. The impeller blade transfers energy to the fluid in the form of kinetic energy and pressure energy. The pump can't rotate in the reverse direction and the correct direction of rotation is clockwise, which can be seen from the back of the motor.  Product Showcase

Product Showcase

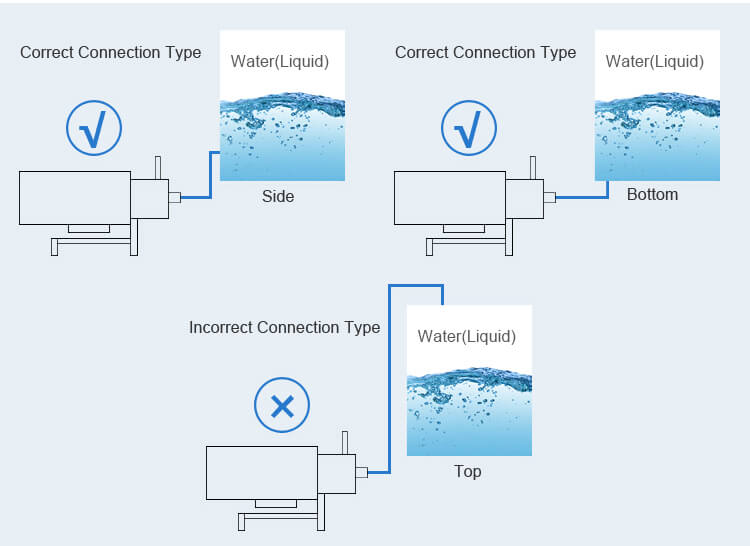

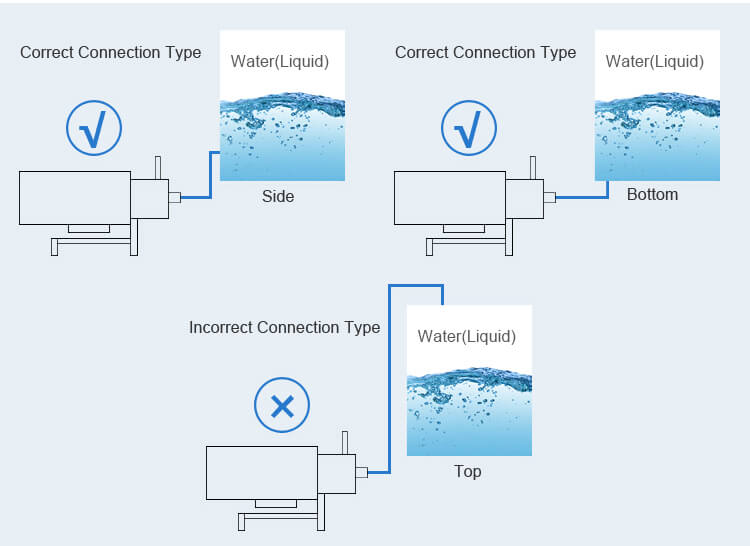

The impeller is integrated with stamping and is directly mounted on the output shaft of the motor, with large strength, unique design, easy installation and high precision. The motor has the advantages of high power, large torque, low temperature rise and low vibration. The three-phase motor directly drives the grinding head, saving grinding time. There are 3 kinds of connection methods, namely clamp connection, thread connection and flange connection. The default connection method is clamp connection. Q & A Q1: What is the lift and flow of this pump? A1: The lift and flow of this pump is based on motor power. You can tell us your required flow and head, our engineers will customize the motor for you. Q2: What is the motor brand? A2: The brand of non-explosion-proof motor is Dedong, and the explosion-proof motor brand is HuXin. If customers require other brands of motor, such as ABB, Siemens, etc., we can also customize it. Q3: What is the connection type of the pump? A3: There are three connection types, namely clamp connection, thread connection and flange connection. The default connection method is clamp connection. Q4: What is concentration of the materials that can be conveyed by the pump? A4: The highest concentration is 0.4. Generally, the liquid can be transported as long as it can flow automatically. Q5: What is the maximum working temperature of the pump? A5: The maximum working temperature is 150 degrees Celsius, and both double seals and water cooling should be used when it is above 100 degrees Celsius. Q6: Is there any explosion-proof motor and variable frequency motor available? A6: Yes, the explosion-proof motor or variable frequency motor is available according to customers’ requirement, but the standard motor is non-explosion-proof and non-variable frequency motor. Q7: What is the material of the pump? A7: The standard material is 304 stainless steel, and if require 316L stainless steel please advise us before placing the order. Q8: What is the motor voltage? A8: The standard voltage in China is 3 phase/380v/50hz, and if any other voltage is required, please check with us before order confirmation. Installation Instructions Installation Method and Place: It is very necessary to check the following before installation: ◎The drive is in good condition. ◎Whether the on-site power supply is the same as the rated power on the motor nameplate. ◎Whether it meets the environmental conditions (avoid flammable and explosive environment or acid corrosion environment). Installation Location: The installation foundation of the pump should generally be level and sufficient-strengthened ground. Install it as far as possible on the lowest position of the equipment, that is, at the position with the maximum head height. Piping Installation: The diameter of pump、 pipe and the inlet and outlet of the pump should be the same, and the diameter of the inlet pipe should not be too small. When the diameter of the pipe is smaller than the diameter of the pump, adjust it with an eccentric reducer to shorten the diameter of the pipe so as to avoid formation of a gas leak. The outlet pipe diameter must not be too large either. When the outlet pipe diameter is larger than the pump outlet, try to extend it. Distance from the pump outlet to avoid overloading the pump motor.

The impeller is integrated with stamping and is directly mounted on the output shaft of the motor, with large strength, unique design, easy installation and high precision. The motor has the advantages of high power, large torque, low temperature rise and low vibration. The three-phase motor directly drives the grinding head, saving grinding time. There are 3 kinds of connection methods, namely clamp connection, thread connection and flange connection. The default connection method is clamp connection. Q & A Q1: What is the lift and flow of this pump? A1: The lift and flow of this pump is based on motor power. You can tell us your required flow and head, our engineers will customize the motor for you. Q2: What is the motor brand? A2: The brand of non-explosion-proof motor is Dedong, and the explosion-proof motor brand is HuXin. If customers require other brands of motor, such as ABB, Siemens, etc., we can also customize it. Q3: What is the connection type of the pump? A3: There are three connection types, namely clamp connection, thread connection and flange connection. The default connection method is clamp connection. Q4: What is concentration of the materials that can be conveyed by the pump? A4: The highest concentration is 0.4. Generally, the liquid can be transported as long as it can flow automatically. Q5: What is the maximum working temperature of the pump? A5: The maximum working temperature is 150 degrees Celsius, and both double seals and water cooling should be used when it is above 100 degrees Celsius. Q6: Is there any explosion-proof motor and variable frequency motor available? A6: Yes, the explosion-proof motor or variable frequency motor is available according to customers’ requirement, but the standard motor is non-explosion-proof and non-variable frequency motor. Q7: What is the material of the pump? A7: The standard material is 304 stainless steel, and if require 316L stainless steel please advise us before placing the order. Q8: What is the motor voltage? A8: The standard voltage in China is 3 phase/380v/50hz, and if any other voltage is required, please check with us before order confirmation. Installation Instructions Installation Method and Place: It is very necessary to check the following before installation: ◎The drive is in good condition. ◎Whether the on-site power supply is the same as the rated power on the motor nameplate. ◎Whether it meets the environmental conditions (avoid flammable and explosive environment or acid corrosion environment). Installation Location: The installation foundation of the pump should generally be level and sufficient-strengthened ground. Install it as far as possible on the lowest position of the equipment, that is, at the position with the maximum head height. Piping Installation: The diameter of pump、 pipe and the inlet and outlet of the pump should be the same, and the diameter of the inlet pipe should not be too small. When the diameter of the pipe is smaller than the diameter of the pump, adjust it with an eccentric reducer to shorten the diameter of the pipe so as to avoid formation of a gas leak. The outlet pipe diameter must not be too large either. When the outlet pipe diameter is larger than the pump outlet, try to extend it. Distance from the pump outlet to avoid overloading the pump motor.

Cosmetic Making Equipment,

Food Oil Filter Machine,

Mobile Lifter,

Beer Fermentation Tank,

Duplex Cartridge Filter,

Butterfly Mixer Grinder,

Heating Mixer Boiler,

Corn Grinder,

Coconut Oil Processing Machine,

Sauce Cooking Equipment,

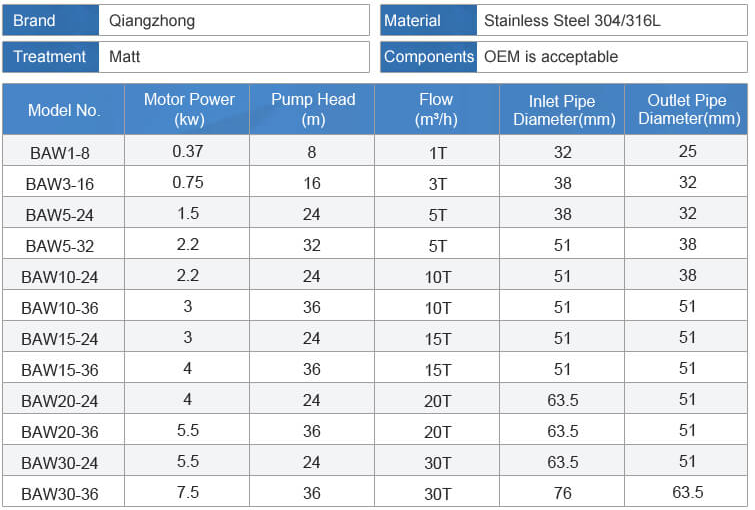

Product Parameters

Product Parameters  Product Structure ● The is mainly composed of a pump body, a pump base, and a motor part. Each part is connected by a bolt. The supporting feet of the base can be freely adjusted to facilitate installation without a fixed mounting base. The outlet pipe can be installed vertically or horizontally according to different needs. ● It adopts a smooth transition, rigid structure and thick-walled design. The parts including the pump body, pump cover, impeller part and the part in contact with the material are all made of stainless steel (AISI316 or AISI304). Mechanical shaft seals are made of high quality stainless steel and silicon carbide. Greatly improved wear resistance and moisturization, extending the useful life. ● The pump body and the impeller adopt the integral precision casting and surface of all parts are treated. With special fixtures to assist installation, ensuring an accurate dimensional clearance. The shaft seal adopts the open type structure, so even a small amount of leakage at the shaft seal can be observed in time. It also ensures that even if the leakage is not noticed within a short time, it will not overflow in the motor, thus ensuring a good service life of the motor.

Product Structure ● The is mainly composed of a pump body, a pump base, and a motor part. Each part is connected by a bolt. The supporting feet of the base can be freely adjusted to facilitate installation without a fixed mounting base. The outlet pipe can be installed vertically or horizontally according to different needs. ● It adopts a smooth transition, rigid structure and thick-walled design. The parts including the pump body, pump cover, impeller part and the part in contact with the material are all made of stainless steel (AISI316 or AISI304). Mechanical shaft seals are made of high quality stainless steel and silicon carbide. Greatly improved wear resistance and moisturization, extending the useful life. ● The pump body and the impeller adopt the integral precision casting and surface of all parts are treated. With special fixtures to assist installation, ensuring an accurate dimensional clearance. The shaft seal adopts the open type structure, so even a small amount of leakage at the shaft seal can be observed in time. It also ensures that even if the leakage is not noticed within a short time, it will not overflow in the motor, thus ensuring a good service life of the motor.  Working Principle Stainless steel sanitary pump (also known as milk pump, beverage pump) is a single-stage, single-suction sanitary pump, suitable for conveying milk, beverages, wine and other liquids. It is an indispensable conveying equipment for food, chemical, pharmaceutical and other industries. It is particularly suitable to be used in tube-type sterilization, yogurt temperature-holding equipment, CIP cleaning and other resistance systems. The impeller is inside the pump casing and it rotates with the pump shaft. The impeller blade transfers energy to the fluid in the form of kinetic energy and pressure energy. The pump can't rotate in the reverse direction and the correct direction of rotation is clockwise, which can be seen from the back of the motor.

Working Principle Stainless steel sanitary pump (also known as milk pump, beverage pump) is a single-stage, single-suction sanitary pump, suitable for conveying milk, beverages, wine and other liquids. It is an indispensable conveying equipment for food, chemical, pharmaceutical and other industries. It is particularly suitable to be used in tube-type sterilization, yogurt temperature-holding equipment, CIP cleaning and other resistance systems. The impeller is inside the pump casing and it rotates with the pump shaft. The impeller blade transfers energy to the fluid in the form of kinetic energy and pressure energy. The pump can't rotate in the reverse direction and the correct direction of rotation is clockwise, which can be seen from the back of the motor.  Product Showcase

Product Showcase

The impeller is integrated with stamping and is directly mounted on the output shaft of the motor, with large strength, unique design, easy installation and high precision. The motor has the advantages of high power, large torque, low temperature rise and low vibration. The three-phase motor directly drives the grinding head, saving grinding time. There are 3 kinds of connection methods, namely clamp connection, thread connection and flange connection. The default connection method is clamp connection. Q & A Q1: What is the lift and flow of this pump? A1: The lift and flow of this pump is based on motor power. You can tell us your required flow and head, our engineers will customize the motor for you. Q2: What is the motor brand? A2: The brand of non-explosion-proof motor is Dedong, and the explosion-proof motor brand is HuXin. If customers require other brands of motor, such as ABB, Siemens, etc., we can also customize it. Q3: What is the connection type of the pump? A3: There are three connection types, namely clamp connection, thread connection and flange connection. The default connection method is clamp connection. Q4: What is concentration of the materials that can be conveyed by the pump? A4: The highest concentration is 0.4. Generally, the liquid can be transported as long as it can flow automatically. Q5: What is the maximum working temperature of the pump? A5: The maximum working temperature is 150 degrees Celsius, and both double seals and water cooling should be used when it is above 100 degrees Celsius. Q6: Is there any explosion-proof motor and variable frequency motor available? A6: Yes, the explosion-proof motor or variable frequency motor is available according to customers’ requirement, but the standard motor is non-explosion-proof and non-variable frequency motor. Q7: What is the material of the pump? A7: The standard material is 304 stainless steel, and if require 316L stainless steel please advise us before placing the order. Q8: What is the motor voltage? A8: The standard voltage in China is 3 phase/380v/50hz, and if any other voltage is required, please check with us before order confirmation. Installation Instructions Installation Method and Place: It is very necessary to check the following before installation: ◎The drive is in good condition. ◎Whether the on-site power supply is the same as the rated power on the motor nameplate. ◎Whether it meets the environmental conditions (avoid flammable and explosive environment or acid corrosion environment). Installation Location: The installation foundation of the pump should generally be level and sufficient-strengthened ground. Install it as far as possible on the lowest position of the equipment, that is, at the position with the maximum head height. Piping Installation: The diameter of pump、 pipe and the inlet and outlet of the pump should be the same, and the diameter of the inlet pipe should not be too small. When the diameter of the pipe is smaller than the diameter of the pump, adjust it with an eccentric reducer to shorten the diameter of the pipe so as to avoid formation of a gas leak. The outlet pipe diameter must not be too large either. When the outlet pipe diameter is larger than the pump outlet, try to extend it. Distance from the pump outlet to avoid overloading the pump motor.

The impeller is integrated with stamping and is directly mounted on the output shaft of the motor, with large strength, unique design, easy installation and high precision. The motor has the advantages of high power, large torque, low temperature rise and low vibration. The three-phase motor directly drives the grinding head, saving grinding time. There are 3 kinds of connection methods, namely clamp connection, thread connection and flange connection. The default connection method is clamp connection. Q & A Q1: What is the lift and flow of this pump? A1: The lift and flow of this pump is based on motor power. You can tell us your required flow and head, our engineers will customize the motor for you. Q2: What is the motor brand? A2: The brand of non-explosion-proof motor is Dedong, and the explosion-proof motor brand is HuXin. If customers require other brands of motor, such as ABB, Siemens, etc., we can also customize it. Q3: What is the connection type of the pump? A3: There are three connection types, namely clamp connection, thread connection and flange connection. The default connection method is clamp connection. Q4: What is concentration of the materials that can be conveyed by the pump? A4: The highest concentration is 0.4. Generally, the liquid can be transported as long as it can flow automatically. Q5: What is the maximum working temperature of the pump? A5: The maximum working temperature is 150 degrees Celsius, and both double seals and water cooling should be used when it is above 100 degrees Celsius. Q6: Is there any explosion-proof motor and variable frequency motor available? A6: Yes, the explosion-proof motor or variable frequency motor is available according to customers’ requirement, but the standard motor is non-explosion-proof and non-variable frequency motor. Q7: What is the material of the pump? A7: The standard material is 304 stainless steel, and if require 316L stainless steel please advise us before placing the order. Q8: What is the motor voltage? A8: The standard voltage in China is 3 phase/380v/50hz, and if any other voltage is required, please check with us before order confirmation. Installation Instructions Installation Method and Place: It is very necessary to check the following before installation: ◎The drive is in good condition. ◎Whether the on-site power supply is the same as the rated power on the motor nameplate. ◎Whether it meets the environmental conditions (avoid flammable and explosive environment or acid corrosion environment). Installation Location: The installation foundation of the pump should generally be level and sufficient-strengthened ground. Install it as far as possible on the lowest position of the equipment, that is, at the position with the maximum head height. Piping Installation: The diameter of pump、 pipe and the inlet and outlet of the pump should be the same, and the diameter of the inlet pipe should not be too small. When the diameter of the pipe is smaller than the diameter of the pump, adjust it with an eccentric reducer to shorten the diameter of the pipe so as to avoid formation of a gas leak. The outlet pipe diameter must not be too large either. When the outlet pipe diameter is larger than the pump outlet, try to extend it. Distance from the pump outlet to avoid overloading the pump motor.