Single-wall Mixing Tank

It can stir, blend, reconcile and homogenize materials. It is made of high-quality stainless steel304 and 316L. The structure and configuration can be customized according to therequirements of the production process.

Product introduction This equipment meets the requirements of China's "GMP"; and is designed and manufactured in accordance with China's JB/4735-1997 standards. This equipment is suitable for pharmaceutical industry, food industry, brewing industry, as well as liquid preparation (product) process and various water treatment processes.- The material is made of 316L or 304 stainless steel, the inner surface is polished, and the roughness(Ra) is less than 0.4pm.

- The mixing method includes top mechanical mixing and bottom mixing:

- Optional configurations are: air breathing apparatus, thermometer, steam sterilization port, sanitary inlet, liquid level gauge and liquid level automatic control system, universal rotating CIP cleaning ball, etc.

- Optional Jacket types include coiled tube, full jacket, and honeycomb jacket.

- The insulation could be rock wool, polyurethane foam, or pearl cotton. The shell is polished, brushed or matted, at the customer's choice

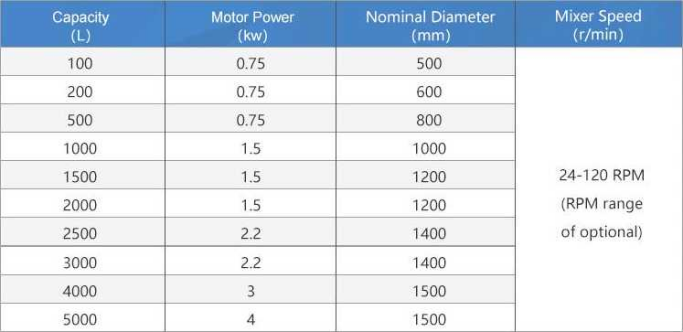

- Capacity: 30L-30000L.

* the above table is for reference only, can customize according to customer's requirements. * this equipment can customize according to customer's material, need to comply with process, such as meet high viscosity, homogeneous function strengthen, heat-sensitive materials such as requirements. GJ PRODUCT STRUCTURE The mixing tank is composed of the mixing tank body, upper and lower ends, agitator, feet, transmission devices, shaft sealing devices, etc., and heating or cooling devices can be added as needed. According to different process requirements, stainless steel or carbon steel can be used for tank body, tank cover, agitator and shaft seal. The tank body and the tank cover can be connected by flange sealing or welding. Different holes can be opened on the tank body and tank cover for feeding, discharging, observation, temperature measurement, pressure measurement, steam fractionation, safe venting, etc. A transmission device (motor or reducer) is installed on the tank cover to drive the agitator in the mixing tank. The shaft sealing device is optional from mechanical seal, packing seal and labyrinth seal. According to different needs, the agitator could be paddle type, anchor type, frame type, screw type, etc. If you have any other customization requirements, please confirm with us.

* the above table is for reference only, can customize according to customer's requirements. * this equipment can customize according to customer's material, need to comply with process, such as meet high viscosity, homogeneous function strengthen, heat-sensitive materials such as requirements. GJ PRODUCT STRUCTURE The mixing tank is composed of the mixing tank body, upper and lower ends, agitator, feet, transmission devices, shaft sealing devices, etc., and heating or cooling devices can be added as needed. According to different process requirements, stainless steel or carbon steel can be used for tank body, tank cover, agitator and shaft seal. The tank body and the tank cover can be connected by flange sealing or welding. Different holes can be opened on the tank body and tank cover for feeding, discharging, observation, temperature measurement, pressure measurement, steam fractionation, safe venting, etc. A transmission device (motor or reducer) is installed on the tank cover to drive the agitator in the mixing tank. The shaft sealing device is optional from mechanical seal, packing seal and labyrinth seal. According to different needs, the agitator could be paddle type, anchor type, frame type, screw type, etc. If you have any other customization requirements, please confirm with us.

- Please operate strictly according to the working pressure and working temperature calibrated on the product nameplate to avoid danger.

- Maintain the equipment in strict accordance with the regulations on cooling and oiling in the product manual.

- Th© mixing tank is gonerally atmospheric oquipment, and should b© operated in accordance wi:h the operating rules of atmospheric equipment.

- For production process with high sanitary requirements (for example in dairy and pharmaceutical industries), the cleaning and daily maintenance should be strictly operated. Please refer to the operating instructions of the equipment for details.

- Please check whether the equipment is seriously damaged or deformed during transportation, and whether the fasteners of the equipment are loose.

- Please use pre-embedded anchor bolts to install the equipment horizontally on a firm foundation.

- Please install equipment, electrical control devices and accessories correctly under the guidance of professionals. Please check: 1). Whether the pipeline is unblocked; 2). Whether the meter is in good condition; 3). Whether the meter is installed correctly. Before starting the device, please check the device itself and its surroundings to see if there are any objects or people that may affect the normal operation of the device to avoid danger.

- After installation, please conduct a trial run for a few seconds first, and make sure that there is no eiectrical short circuit or abnormal sound before a short trial run.

- If the mixing tank is equipped with a mechanical seal, an appropriate amount of 10# machine oil or sewing machine oil must be injected into the machine seal lubrication tank before the main engine is started. Cooling water must be passed into the cooling chamber of the mechanical seal to make the mechanical seal device well lubricated and cooled. Since the mechanical seal is not adjusted at the factory, please adjust the mechanical seal to the best position according to the installation manua: after the equipment is installed, before it can operate normally.

- After the equipment is running normally, please check the bearing temperature, running smoothness, tightness, etc., as well as whether the instrument is working normally. The feeding operation can be carried out after confirming that it is normal.

- confirming that it is normal.